The biohack.me forums were originally run on Vanilla and ran from January 2011 to July 2024. They are preserved here as a read-only archive. If you had an account on the forums and are in the archive and wish to have either your posts anonymized or removed entirely, email us and let us know.

While we are no longer running Vanilla, Patreon badges are still being awarded, and shoutout forum posts are being created, because this is done directly in the database via an automated task.

SMM and others - an analysis

I'm working on an analysis of some magnets. It isn't complete, but I think it will answer a number of the questions that have been posted recently. I'll update y'all with more info on the SMM results later. Here's a link:

Comments

-

Love the write up!

-

Really good analysis will definitely be watching to see what happens. I also had a question for you. I've seen some people talking about you making a resin coating for magnets. Could you give me a link to where you have talked about this in detail?

-

Hey Boi, I'm really cautious about what I say at this point. Once misinformation gets into the community it never dies. One person 10 years ago talks about Sugru and people are still trying the shit out. The coating type I'm trialling is PMMA.. an acrylic. Specifically with a uv curing agent. I totally showed off the brand at grindfest but have as of yet been reluctant to share it here. I've had two people receive fucking massive wads of this shit as an implant. Healing was rapid and they've gotten serial blood tests down with no change in liver enzymes levels. My plan is to release this info at the one year point. I'm hoping it's going to be our solution for rapid prototyping.

Basically, it's no trade secret. I was at first really critical towards the SMM magnet.. but having found the additional layer of metal I'm hopeful. We may have a god damn 10 dollar biocompatible n52. We'll see.

For those asking, yes. I'm willing to make another batch of pellucids magnets. I want to point out though that the HWT magnet has gone down considerably in price. I think it's 60 bucks right now? That about what it costs me to make the ones I do. -

Next week, I'll put an order form live again on my site and put a link here.

-

All of that sounds promising. I was contemplating implanting one of the SMM magnets soon. I was kinda waiting to see how @nothot 's had gone and to see what you had to say about it. At this point it is seeming to be relatively good option. If things keep going good and I get some free time I'll go ahead and do it. I'll be sure to watch it and let everyone know how it goes.

-

Also by the way I am speaking with someone at SMM to try and get more info on what the other metal layers if the magnet are. If I find out Ill post them here.

-

Oh cool. Let me know. I personally wouldn't put anything in my body without it surviving a minimum of three months of saline. I even ship everything I make in saline. Part of that is to maintain cleanliness but it also give the magnet more opportunities to fail. If it's going to fail at all... I want it to fail before implant. Ideally, we'd treat this shit like wine... It's been in saline since 73 and still looks great!

-

That's true that's kind of why I'm waiting on some results from you and @nothot

-

Thanks, Cassox. I look forward to seeing your notes. I'd definitely recommend diamond paste polishing the SMM magnets. I made 4, and have left the 3 spares in saline to monitor. Minor editorial note: "The claim by SMM to be an N52 is most likely false.". I believe you meant "N55" there.

Cheers -

I emailed smm while ago and asked about the coatings, they told me that its bare magnet and tin so what the heck is going on lol

-

TiN is titanium nitride, not the element tin (Sn).

-

I know that lol. But apparently there is some unknown coating under the TiN as seen

-

I've sent them an email about it so we'll see if they tell me anything else.

-

I got a response and the SMM rep said, "Thank you for you request. There is double coating of titanium nitride over a standard nickel coating (NiCuNi)." This is confusing since there was some other layer in your testing. I sent another email explaining that there seemed to be yet another layer so I'm waiting on them to respond.

-

Interesting. Exited to hear what they answer lol

-

The SMM rep said that he was going to get in contact with the factory who coated the magnets and try to find out what the mystery layer could be. He should have that info by tomorrow.

-

Thats weird, so they dont coat their magnets by themselfs?

-

The equipment for coating with parylene or TiN is pretty specialized and pricey.

-

To be honest, Im not sure they even make the magnets.

-

@cassox im starting to think so too. They dont know anything about their "own" magnets lol. Something fishy clearly going on:D

Hey but atleast now we can get cheap tin "n55" magnets! -

Oh, I didn't mean that how it sounded really. I mean, maybe.. But I think it's a distributor. I've ordered larger batches from china before. Like anything else, purchasing in bulk and reselling is fine. Especially if you make effort to select for quality. It's just even like K and J I think is from China. I order from them and like the company. I'm totally not at the point that I think these things are safe to implant. Still testing. But yeah, if they turn out to be good then who cares right?

-

Great report! So far so good with my implant other than some minor scaring around the magnet in my finger. Not sure if it’ll ever go away. I didn’t realize I should’ve washed the magnet with soap(although I did soak it in isopropyl and cleaned with chlorhexidine) so the scar could be from the leftover soot you found in your report. I doubt it’s failing since there’s no discoloration or pain in my finger.

-

Post deleted

-

The SMM rep had no more info today. They said they only have the NiCuNi then double TiN. He said maybe there was a chance you didn't completely scrape all of the TiN off. They didn't have much info past that.

-

Weird

-

Interesting. Did he have any information regarding the scorching?

-

It's possible there's some technical explanation that escapes me. For example, welding of titanium requires gas shielding because when the outermost layer is exposed to air it forms an oxide layer with different characteristics.

Coating technology is weird. Maybe the initial layers laid down have different mechanical characteristics then the rest. I don't know. I'll be back at the lab tomorrow and have updates. -

Magnet Analysis Followup and Other Fun

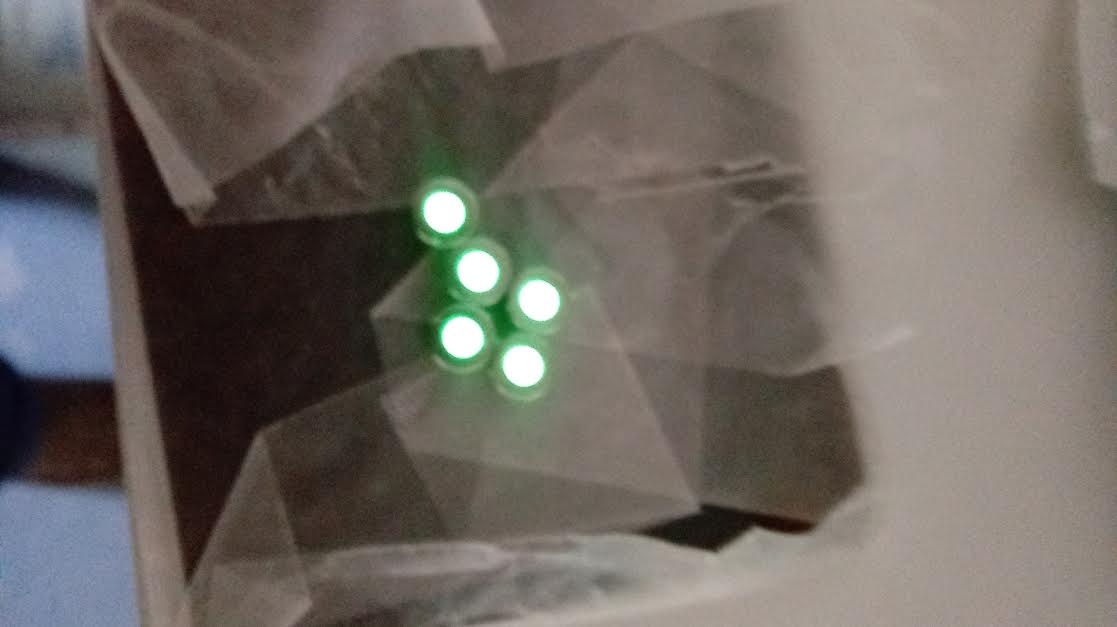

For those interested, there's a short follow up on the SMM magnet tests and a pic of the phosphorescent magnet implants I've been working on.

-

-

Are these the phosphorescent resin ones, or did you end up doing something different? You mentioned the resin was really brittle.