The biohack.me forums were originally run on Vanilla and ran from January 2011 to July 2024. They are preserved here as a read-only archive. If you had an account on the forums and are in the archive and wish to have either your posts anonymized or removed entirely, email us and let us know.

While we are no longer running Vanilla, Patreon badges are still being awarded, and shoutout forum posts are being created, because this is done directly in the database via an automated task.

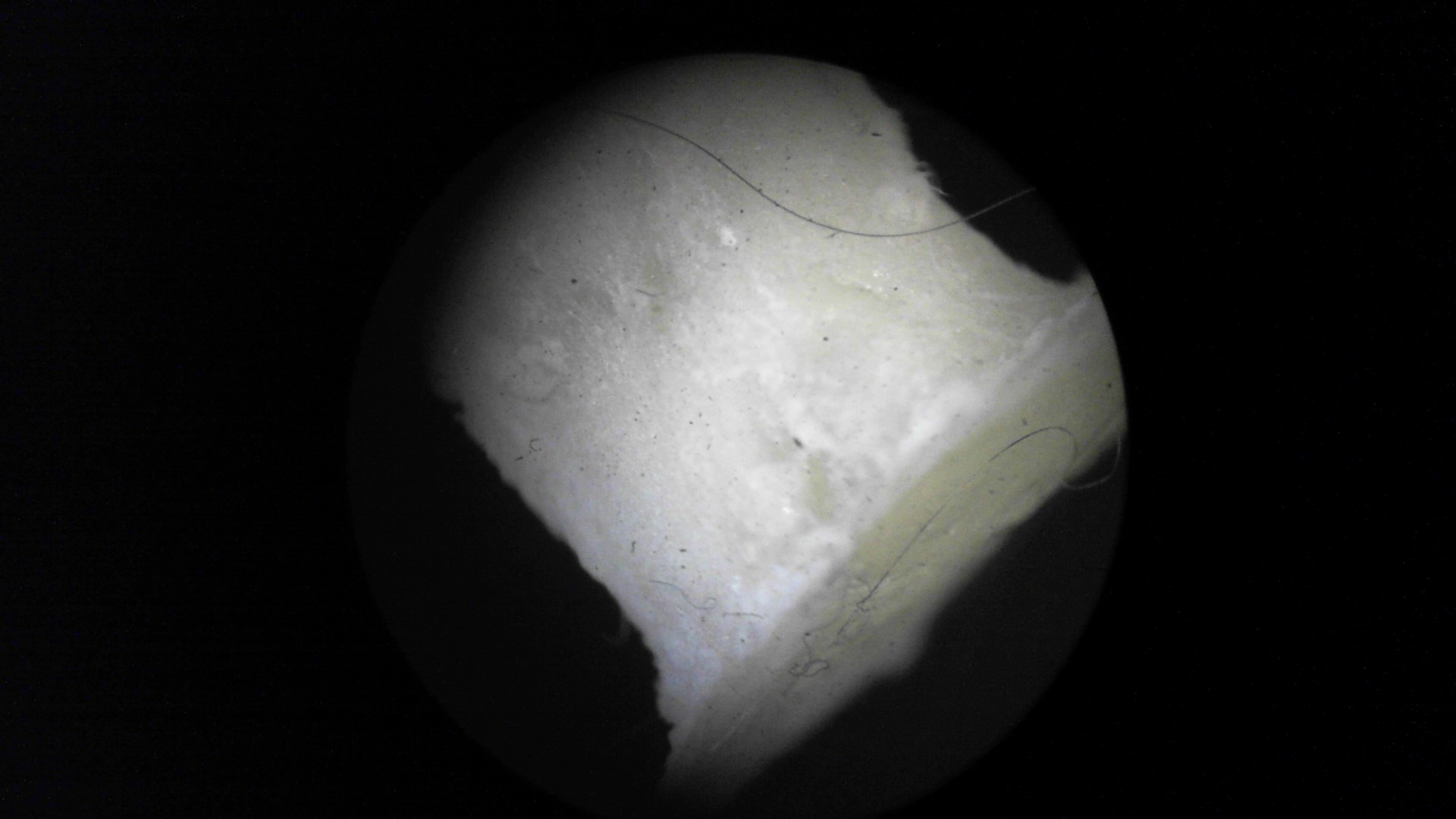

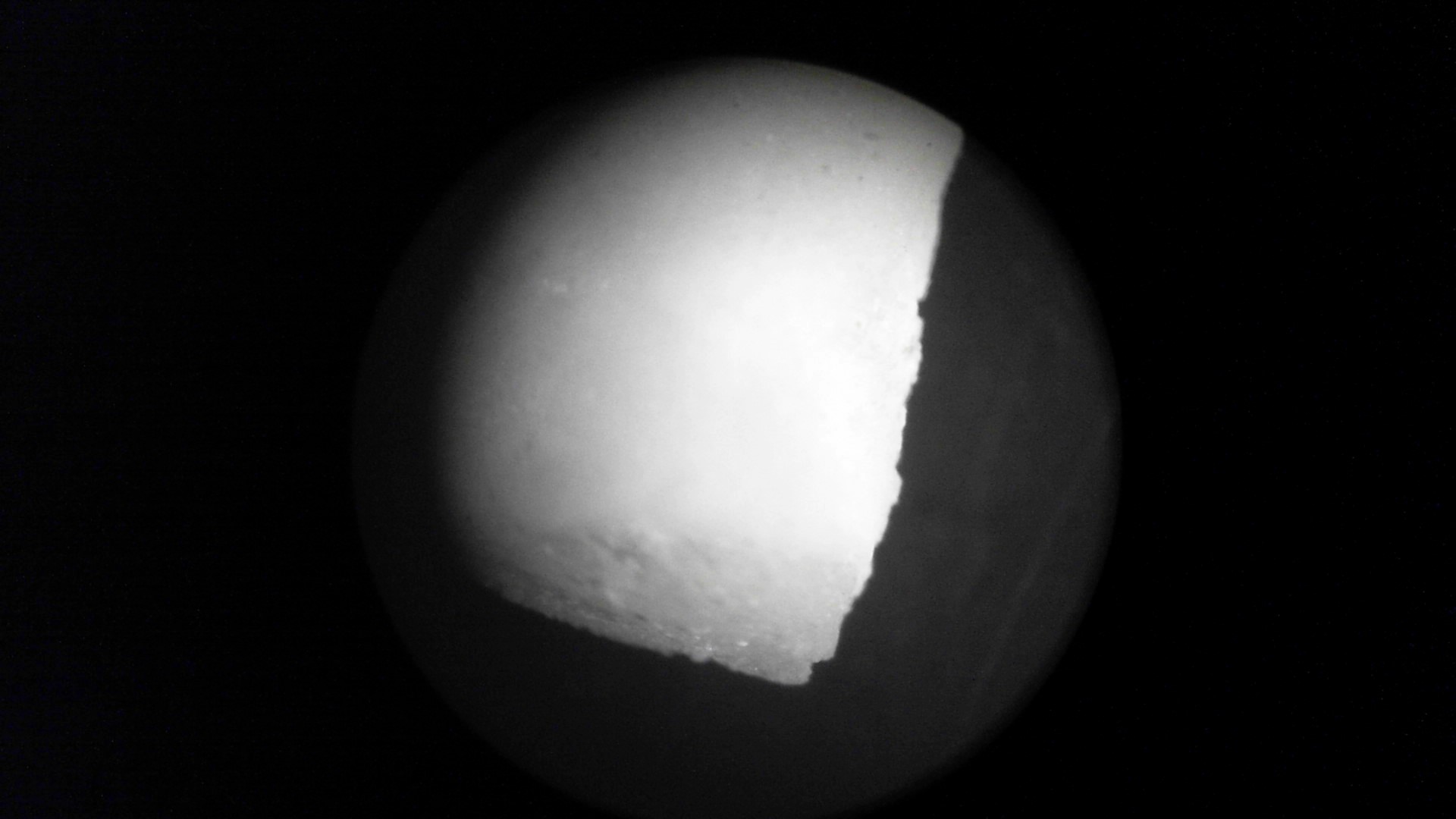

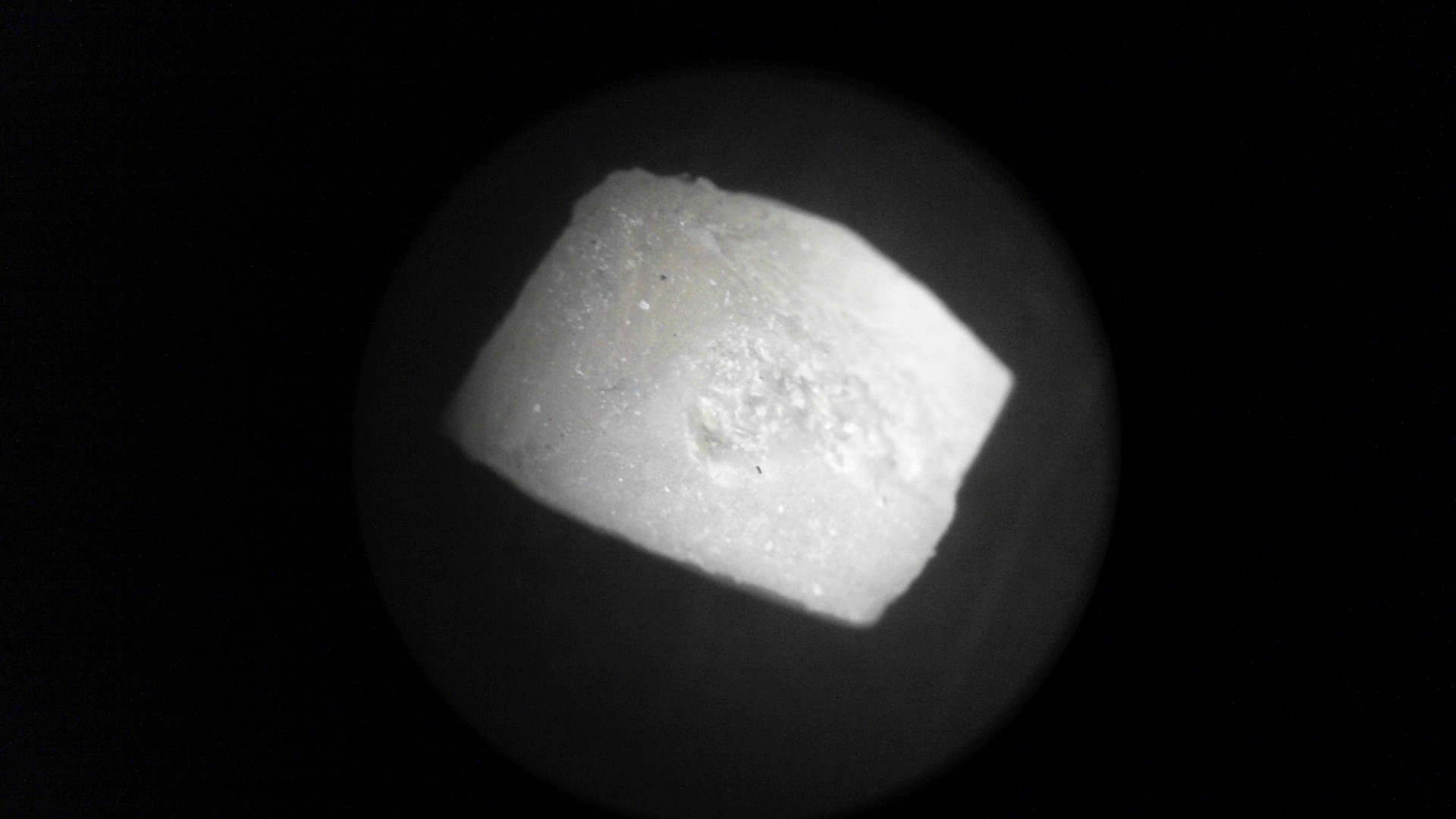

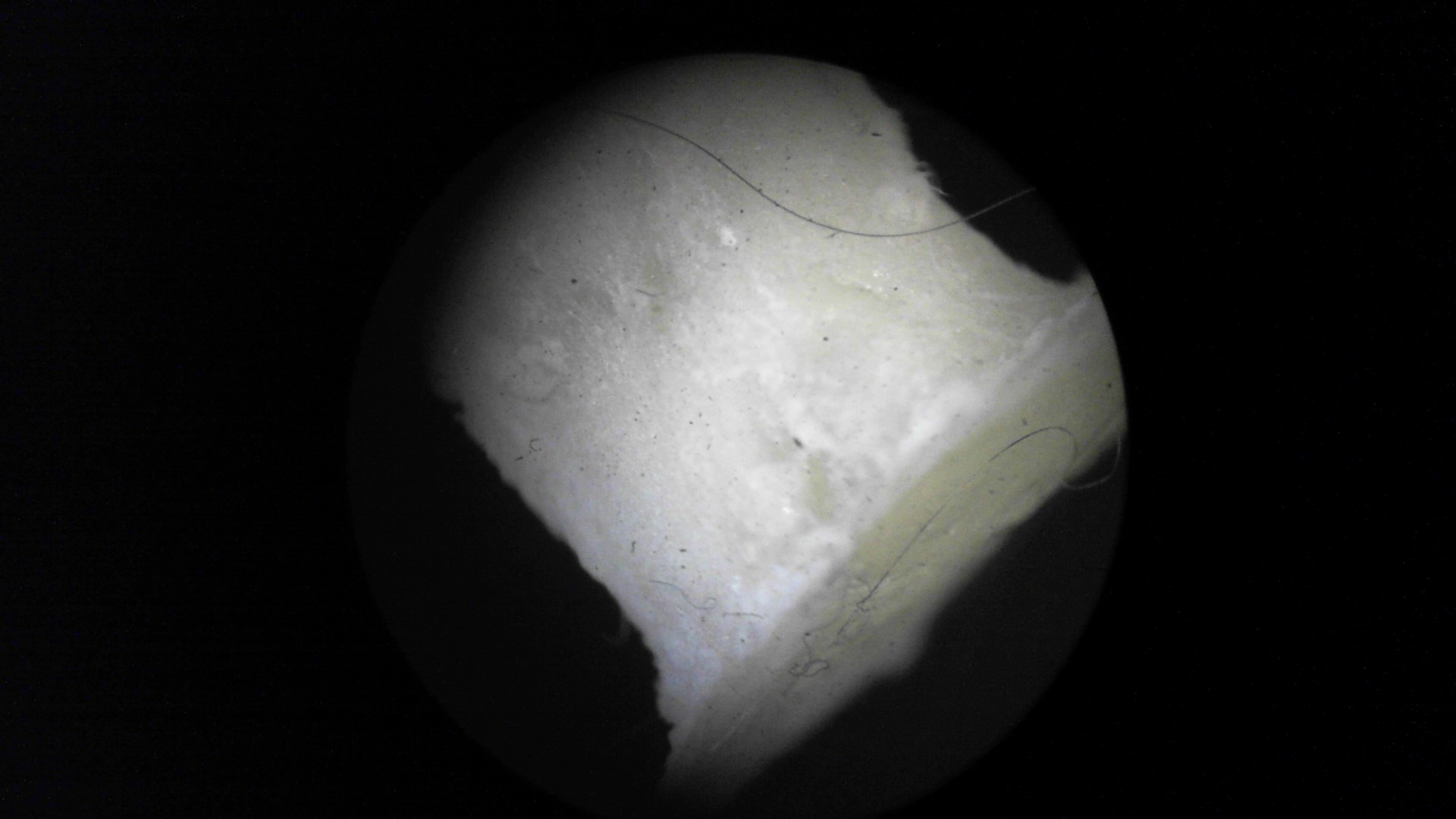

Atom Adhesives Samples

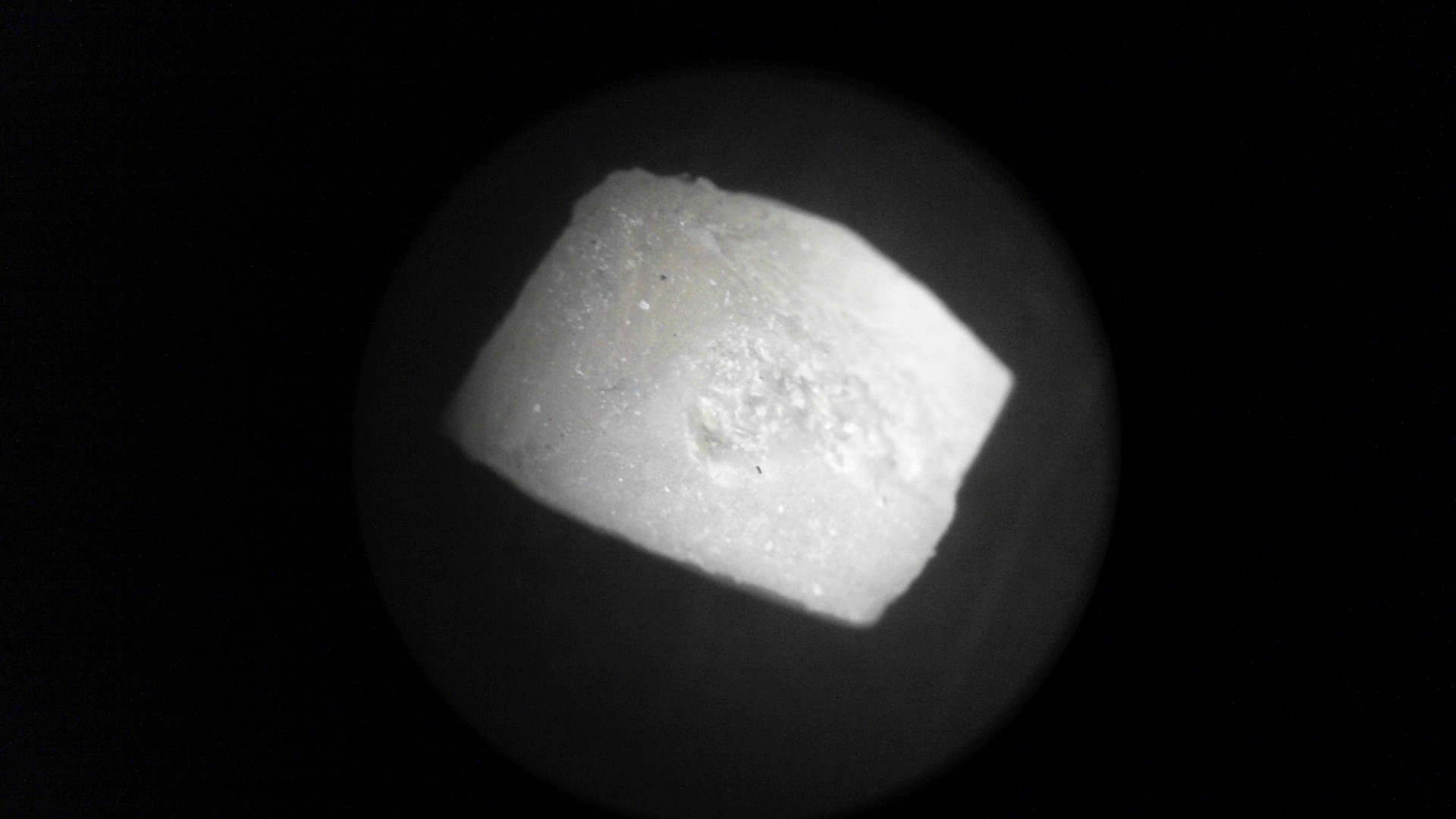

I've started working with this stuff a bit more. Thought I'd shoot up a few pics. The piece I was working with was too small. I couldn't hold it well enough to get a good polish. I also found a small area that didn't seem entirely crosslinked. I'll be baking up some larger samples to play with soon. I'll let you know when and if I get this stuff into a form I think would be acceptable for implantation. At this time, I think a mold system would probably be better than trying to sand and polish.

Comments

Displaying all 11 comments

-

is this the exact same stuff that I was messing with or a different product from them?

-

Exactly. its the same stuff. I used the same air stone stuff as a mold. The reason it doesn't look translucent in these pics is a combination of lighting and having been sanded. I'll take pics during each step this next time.

-

This is why I said sanding will be iffy. Unless you have a rock hard resin it'll be very difficult to try and sand it smooth. it'd be like trying to sand an eraser. won't go well. Even if it looks smooth the imperfections will still be enough to cause rejections. And the pictures just highlight that. Better to spray coat the part, gives a better finish if possible.

-

I was planning on doing some 3D prints of the mold and using a silicone to coat the inside and coat things that way. Im hoping that it will make for a no sand smooth finish.

-

So I have been running some tests and found that this coating dissolves into a kind of rubbery soft gel if you leave it in isopropyl alcohol for a few days. But the hydrogen peroxide and water seam to be holding up just A OK. Just though I should give an update on how my finding are going.I'm not good at the bio of this stuff so does it even necessarily matter that it got that way in the isopropyl?

-

If your coating collapsed in the iso itt means one of a few things. The iso broke the crosslinking (this can be tested by letting it dry out. Does it turn solid of stay jelly? Jelly means you broke it), the iso was absorbed by the polymer matrix (Turns hard when dry but returns to basic shape after drying), or the iso loosened the polymer matrix causing it to collapse. It would be solid but reconfigured after you goo'd it. A great example of this is styrofoam in acetone. Stryrofoam doesn't melt in actetone, it just gets deflated. If you leave it to dry it turns inot a little sad lump of crispy polymer that could, in theory be reinflated.All of these come with their own issues, not just for sterilization, but also in terms of how robust your coating is and how it will respond to certain situations. Obviously a few days of iso aren't realistic, but it is indicative of certain things. Have you tried acetone and ethanol as well? How does it hold up when you dry it via passive convection (no heat)?

-

Ok, I got a nice glass out of it when using a proper mold and held it at 5 days at 130 F, then an additional day at a cool temperature. Here are the pics. http://augmentationlimitles.ipage.com/?p=115

-

-

in a vacuum oven you could bring that up to 80C (176) or even higher. If you have the available materials, I would test your method a little higher temp wise. You can probably get up there without scorching, and this will alter your material properties a bit and get you a faster cure.Granted, you may not want to go any higher, in case what you coat is temp sensitive, but it might be good to know.EDIT: read your post. Saline won't be that good for removing excess solvent. What you would want is an isOH/diH20 mix (60/40) to get out your non polar solvents and then just di as a soak / rinse step. ANd of course, hit it with a vacuum to get it fully dry if possible.IsOH isn't strictly non polar, but it works well enough in this case. Also, it shouldn't mess with your crosslinking, since it is fully set now. If it does, let us know, cause that means something is weird.

-

Hey, any progress on this? I still feel like this stuff has promise...

-

on Tuesday I implanted 2 large disk magnets coated in this stuff in the side of my hand.The healing process have been extremely fast and easy. I have absolutely no imitation, no redness, itching, anything really. It is still a tad bit swollen from all the cutting, but the magnets are staying in place and my body seams to be perfectly fine with them being in there.I spoke to early before when I was saying that some isopropyl was getting through the coating. it Turned out that those magnets were not perfect coatings. I coated the ones I have in now for about 2 weeks after giving them double coatings and they have absolutely no issue.I have a video here https://youtu.be/FCaOoE8KUEo

Displaying all 11 comments