Building a magnetron

So I've talked about magnetrons on here a few times. They're a vacuum device that allows you to coat something i a thin layer of metal or ceramic even if that thing can't be plated onto. Things like glass, bugs and magnets. Spent the past few weeks working with @thephakt to help her build one of her own so she can experiment with it. We'll be turning all our progress into a video at some point but we had some success and I felt like sharing.

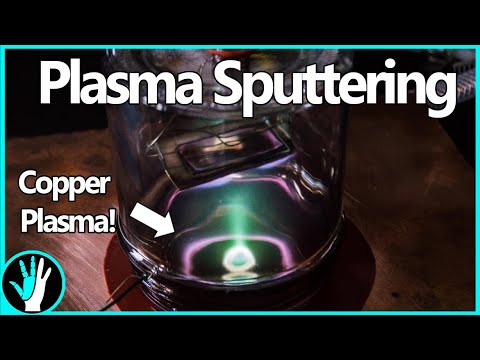

Here's the device after being pumped down for the first time and the high voltage applied:

LINK

And here's it with the manget in place:

LINK

We're controlling it with a scariac that we built:

LINK

LINK

And here's it with the manget in place:

LINK

We're controlling it with a scariac that we built:

LINK

And we made the chamber ourselves:

LINK

Will keep ya'll updated on progress and if we get success coating things in metal.

LINK

Will keep ya'll updated on progress and if we get success coating things in metal.

Tagged:

Comments

My first fusor i did something similar to you, where i drilled the smallest hole possible into a bell jar (trying to compromise the integrity as little as possible, and avoid as much leakage as i can), and stuck steel wire into it for the cathode. Drilling into the top and press fitting a brass nipple and cap (cap was on the inside, and had a hole drilled into it) gave a decent seal, possibly down to 200 microns.

I'd like to be a part of this for idea exchange, and perhaps testing as well.

THE ULTIMATE POST NECRO.

I was tempted to necro my very first post on here as it concerned this project but the title on this one was more apt. SO the short version is, I got the damn thing working finally and can coat just about anything in most metals. Thus far I've successfully done copper silver and gold and am starting to think about platinum or palladium. Still working on titanium though as it's a giant pain in the ass to sputter. I posted a video about the working system a couple weeks ago and will be posting a second follow up in a week or so. Here's a picture of a prototype neural electrode array I'm working on. It's a silver base layer with gold on top to enhance biocompatibility. Gonna turn it into a little petri dish and grow some neurons in it with @glims.

Before you ask, no can't do titanium nitride yet but I'm working up to it. Titanium is a god damn nightmare to get to work. And no I won't coat a magnet for you nor do I intend to coat magnets. But you are welcome to use the design to make your own for coating purposes. But fair warning most coatings made this way can be delicate or imperfect if done improperly. Or ya know, just buy a magnet from dangerous things or cyberise. The point is more that this thing finally works and is dope as fuck so I thought I'd share. Gonna use it for all sort of stuff in the future as it's supppper useful, which is why I tried building one 5 years ago when I first got on here.

TL:DR Magnetron finally works, and it's dope

And here's the video of the first successful runs:

Phenominal work, Chironex. Love watching progress

Second video update, now with patterned metal and 100% more hornets